Nevada is famous for many things: gambling, drive thru weddings, atomic testing, Area 51. It’s likely that none of these things would be possible without the incredible feat of engineering that is the Hoover Dam.

Just 35 miles outside of Las Vegas (not that there was much a ‘Las Vegas’ to be ‘outside of’ back then) in the Black Canyon of the Colorado River, the Hoover Dam was constructed over a 5-year span from 1931 to 1936.

Why Was the Hoover Dam Built?

America was in the depths of the Great Depression, and President Hoover saw an opportunity to address multiple issues at once. Building a dam would:

1. Create work for thousands at a time when nearly a quarter of the population was unemployed.

2. Control flooding.

3. Create a reservoir, so access to water was more predictable and less deadly.

4. Generate enough hydroelectric power to service millions in the region – can you imagine the Las Vegas strip without that electricity?

Hoover Dam Design & Construction

American civil engineer John Lucian Savage supervised the design of the Hoover Dam. It is known as an arch-gravity dam; a type of dam that combines the characteristics of both an arch dam and a gravity dam. (Duh, right?). It is designed to resist the forces of water pressure through a combination of its own weight (that’s the gravity bit) and the arch action. Arch dams resist the horizontal thrust created by the water pressure. It converts the horizontal forces into vertical forces, which are then transferred downwards along the abutments. This arch action helps to counteract the tendency of the dam to overturn or slide downstream.

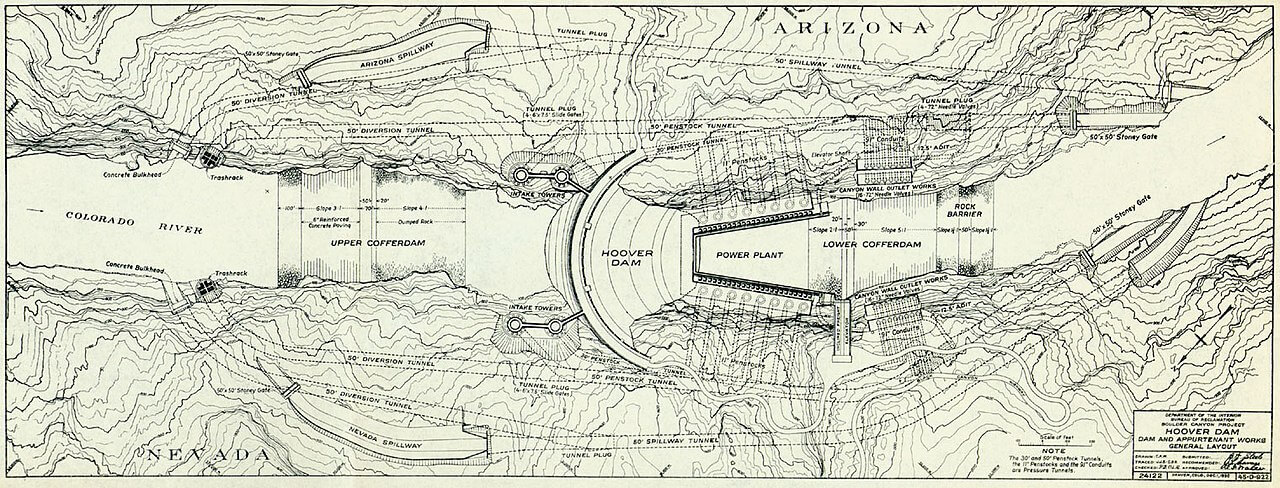

Tunnels & Cofferdams

So how did they build a giant dam amongst dangerous, rushing water? First, they had to build four diversion tunnels and two cofferdams.

At the time of the tunnel construction in May of 1931, no roads in the area had been created yet, so all workers and equipment were transported by boat. Working conditions were tough with extreme heat (140°F in the summer), icy winds in the winter, and regular flood waters.

They essentially bored holes into the rock, filled them with dynamite, and let the explosions do the rest. More than 1.5M cubic yards of rock was removed (“mucked out”) from the tunnels with power shovels and hand tools and trucked down-river by dump trucks. In November 1932, rock and earth were dumped into the channel to block the water and divert it through the man-made tunnels.

Over the winter of 1932 and 1933, the two cofferdams were completed to keep the site dry. The upper cofferdam was 98 feet high, 450 feet long, and 750 feet thick at the base. The lower cofferdam was 66 feet tall, 350 feet long, and 550 feet thick at the base. Unlike modern, water-filled cofferdams, these ones were filled with earth and rock.

The spring floods of 1933 were the real test of the tunnels, cofferdams, and the rock barrier. As planned, they held off the highest waters of the season and construction on the dam foundation could finally begin.

Concrete & Cooling

The Hoover Dam was not created by a single pour of concrete, but rather a series of trapezoidal columns. This is because the heat generated by the curing process would have been so immense that it would have taken 125 years to cure and cool to ambient temperatures. The base required 230 of these interlocking blocks, each of them five feet in height.

Heat was still a problem though. The engineers were worried that the heat would cause dangerous cracks which could compromise the structural integrity of the dam. So they used a previously tested method of using 1-inch cooling coils inside the concrete blocks, circulating chilled water through the pipes. When the concrete block was sufficiently cooled, the pipes were cut off and filled with grout (pressure grouted, in fact). The Hoover Dam had 590 miles of these cooling coils in action. It isn’t clear if the rumors that the Hoover Dam concrete is still curing are true, but core samples taken from 1995 suggest that the unique chemical makeup of the concrete coupled with immense pressure has caused the dam to continue to gain strength over time instead of deteriorate like other concrete structures.

The total amount of concrete used in the Hoover Dam is enough to build a two-lane highway from San Francisco to New York City—that’s a lot of concrete! It is said that it was the first man-made structure to top the masonry mass of the Great Pyramid of Giza.

The Workers: Wages, Occupations, & Support

Competition for jobs was fierce in the 1930s. The average unemployment rate was 18.3% and the average income was close to $1,400 per year for white men (and less than half of that for Black men).

Over 21,000 workers came from all over the country (48 States to be exact)—the most coming from California, Nevada, and Utah—to work on the Hoover Dam project. Considering the average hourly wage for unskilled labor in the mid-1930s was $0.45 per hour, those working on the Hoover Dam were paid quite well for the time. The average wage for workers at the Hoover Dam was $0.63 per hour and the highest was $1.25 (shovel operator). Laborers, miners, jackhammer men, and boat operators made $0.50 – $0.70 per hour while machinists, electricians, mechanics, and crane operators made $0.75 – $1.00 per hour.

Perhaps the most dangerous of all the occupations was removing loose rock before dam construction could begin. These men were known as the “high-scalers”. They had to climb down the canyon on thin ropes, swing over empty spaces, operate jackhammers, and dodge falling rocks. In fact, the many accidents related to falling rocks lead the main contractor to commission commercial hard hats for the men on the project.

The extreme remoteness of the location, coupled with the thousands of men (and their families) coming from across the country to work, meant that dedicated accommodations were needed. And so, Boulder City was born. It wasn’t just a city, it was a community and support system, with all the necessary amenities to help it thrive: houses, schools, shops, a movie theater, and a hospital. Its location near the construction site made the commute easier and helped the project be more efficient.

How Many People Died Building the Hoover Dam?

While the “official” death toll during the construction of the Hoover Dam is 96, old records from 1931 to 1935 suggest that the actual number is slightly higher at 116. Due to poor record keeping and unclear data, the real death toll is unknown, but the table below summarizes the data the Bureau of Reclamation found in the Hoover Dam Project History, volumes 1 through 5.

| 1931 | 1932 | 1933 | 1934 | 1935 | Totals | |

|---|---|---|---|---|---|---|

| Heat Prostration | 16 | 0 | 0 | 0 | 0 | 16 |

| Drowning | 4 | 2 | 0 | 0 | 0 | 6 |

| Blasting | 7 | 2 | 3 | 0 | 0 | 12 |

| Falling Material / Rock | 6 | 5 | 5 | 4 | 0 | 20 |

| Accidental Falls | 1 | 5 | 7 | 6 | 4 | 23 |

| Struck by Equipment | 1 | 10 | 6 | 7 | 6 | 31 |

| Misc. Accidents | 1 | 10 | 1 | 3 | 1 | 8 |

| Totals | 36 | 27 | 22 | 20 | 11 | 116 |

Now, for the big question: are there any bodies buried in the Hoover Dam? Contrary to popular belief, there are no bodies buried in the Hoover Dam. Each segment of concrete took hours to pour and the engineers never would have allowed anything—even a block of wood— to compromise the integrity of the concrete.

Hoover Dam: By the Numbers

- The Hoover Dam stands 726 feet (221 meters) tall and stretches across the canyon for 1,244 feet (379 meters).

- The dam is 660 feet thick at the base and 45 feet thick at the top.

- The total volume of concrete used is approximately 4.4 million cubic yards (3.4 million cubic meters).

- It was a massively expensive undertaking ($49 million, or $760 in today’s dollars) – so much so that six companies had to form a consortium, which they very creatively called Six Companies Inc. It was the largest contract the US government had awarded at the time.

- On average, the dam produces about 4.5 billion kilowatt-hours of electricity per year, supplying power to approximately 1.3 million people in Arizona, Nevada, and California.

- Lake Mead, the Hoover Dam’s reservoir. is one of the largest man-made reservoirs in the United States. It has a total storage capacity of approximately 28.9 million acre-feet (35.7 billion cubic meters) of water when full, which is roughly equivalent to about two years’ worth of the Colorado River’s average flow.

Still an Engineering Marvel

The Hoover Dam remains an iconic symbol of engineering excellence and a major tourist attraction. It showcases the achievements of the men and women who worked on its construction and continues to provide significant benefits to the region to this day.