Heavy equipment like Caterpillar machinery plays a critical role in site preparation, trenching, backfilling, grading, and earthmoving. But with great power comes great risk. Improper operation and oversight can lead to serious injuries, property damage, or even fatalities. This Caterpillar toolbox talk outlines essential safety practices, inspection protocols, and situational awareness tips for operators and ground crews alike.

The Importance of Caterpillar Safety

Operating heavy equipment like Caterpillar machinery is integral to construction projects, but it also presents significant risks when safety protocols are not strictly followed.

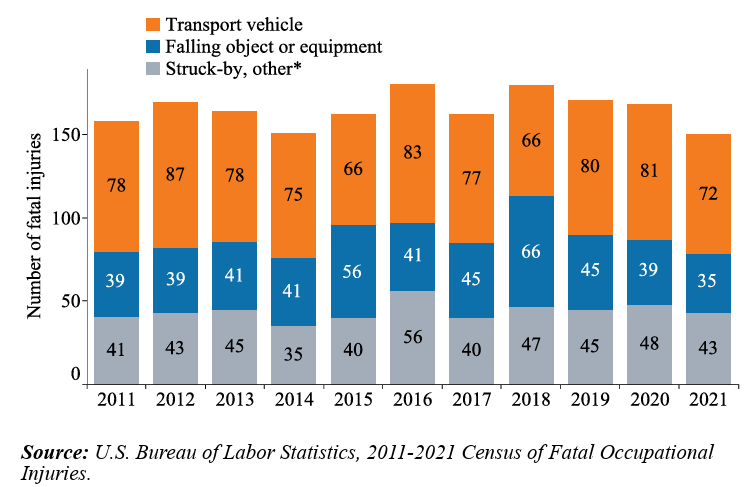

- “Struck-by” incidents are one of OSHA’s Fatal Four construction hazards and account for approximately 17% of jobsites fatalities.

- In 2020, construction transport vehicles accounted for 48% of struck-by deaths in the U.S.

- About 75% of “struck-by” fatalities on the construction site involve heavy equipment.

These incidents underscore the critical importance of comprehensive safety measures, including thorough pre-operation inspections, clear communication among crew members, and adherence to established safety protocols. By prioritizing these practices, we can work towards preventing such tragedies and ensuring a safer working environment for all.

Be Aware of Your Surroundings

Construction sites are dynamic environments. Visibility can be limited, tasks are happening simultaneously, and workers may not always be where you expect them to be. That’s why awareness is your first line of defense (especially when operating large equipment like dozers, excavators, loaders, and backhoes).

Always:

- Complete a 360° walkaround before starting the engine

- Identify and flag all obstacles, hazards, or people within your work zone

- Use a spotter when backing up or working in tight quarters

- Communicate clearly using radios, hand signals, or agreed-upon cues

A moment of inattention can change a life forever. Staying alert keeps everyone safer.

Pre-Operation Inspections

Before starting any Caterpillar machine, a full walkaround inspection is non-negotiable. This helps prevent mechanical failure, ensures OSHA compliance (CFR 1926.601(b)(14)), and protects the operator and surrounding workers.

Pre-trip inspection steps include:

- Checking for visible leaks, damage, or wear

- Verifying fluid levels (engine oil, coolant, hydraulic fluid)

- Inspecting tracks or tires for wear and obstructions

- Testing lights, horns, alarms, and backup systems

- Confirming that attachments are secure and functioning

Use a checklist to ensure consistency. Never assume the last operator caught everything.

Heavy Equipment Safety

Operating Caterpillar equipment safely requires training, attention, and the discipline to follow procedures every time. Operators must understand both the capabilities and limitations of the machine they’re using, as well as the terrain and jobsite conditions.

Key safety rules:

- Always wear seat belts and use ROPS (rollover protection structures) where required

- Never exceed rated lift capacities or travel speeds

- Keep buckets and blades low during travel

- Don’t carry riders or use equipment for unintended purposes

- Shut down and secure equipment when not in use

Operators should also monitor fatigue, distractions, and environmental conditions that may impact control or judgment.

Relevant OSHA Regulations

- CFR 1926:601 Motor Vehicles: Outlines the safety requirements for motor vehicles operating on construction sites. It covers inspection, maintenance, lighting, signaling, and operator awareness to protect both drivers and ground personnel.

- CFR 1926.21(b)(2) Safety Training and Education: Workers must be trained to recognize and avoid unsafe conditions, including struck-by hazards from heavy equipment.

- CFR 1926.651(e) Specific Excavation Requirements: Employees must stay clear of suspended loads and only remain in cabs during loading if the vehicle provides OSHA-compliant operator protection.

- CFR 1926.1000 Rollover Protective Structures; Overhead Protection: Required on crawler tractors, scrapers, front-end loaders, and similar equipment to protect operators in the event of a rollover.

Communication with Ground Crews

Even the best equipment operator can’t see everything. That’s why strong communication between operators and ground crews is essential. One misstep can result in crushed limbs, struck-by injuries, or trench collapses.

Tips for safer communication:

- Establish hand signals and review them before starting work

- Use high-visibility clothing and eye contact when approaching equipment

- Keep a safe distance from swing zones and blind spots

- Never assume the operator sees you and wait for acknowledgment

Making communication part of your jobsite culture can drastically reduce accidents.

Daily Checklists and Documentation

Maintaining a daily checklist log is more than just paperwork, it’s a key part of jobsite accountability. These logs can be used to track equipment condition, schedule repairs, and provide evidence of compliance in the event of an incident or inspection.

Checklist essentials:

- Operator name and machine ID

- Inspection date/time

- Any damage or concerns noted

- Actions taken (e.g., maintenance request, out-of-service)

Digital inspection forms can speed up reporting and reduce errors, especially when multiple machines and operators are in rotation.

Final Thoughts

Caterpillar equipment helps build the world around us—but it demands respect and responsibility. Whether you’re behind the controls or working nearby, taking the time to assess risks, follow procedures, and communicate effectively makes all the difference.

✅ Inspect before you operate

✅ Communicate clearly

✅ Stay alert to your surroundings

✅ Use the right gear and training

Big iron deserves big caution. Make every shift a safe one.